A Comprehensive Guide to the Sorts Of Ceramic Layer on the Market

Ceramic finishes have become a crucial service throughout different sectors because of their unique homes and applications. From silica-based formulations understood for their effectiveness to hybrid alternatives that merge several advantages, the options offered can be frustrating. Understanding the subtleties of each kind, including their details advantages and perfect usage situations, is crucial for making educated decisions. As we discover the distinctive attributes and applications of these finishes, the effects for performance and long life end up being increasingly obvious, elevating inquiries regarding which kind may best suit your needs.

Recognizing Ceramic Coatings

Ceramic layers are innovative safety services that have actually obtained popularity in different sectors, specifically in automobile and aerospace applications. These coverings are composed of a fluid polymer that, when cured, creates a durable, hydrophobic layer on the surface of the substratum. This layer provides boosted resistance to ecological impurities, UV radiation, and chemical direct exposure, thereby prolonging the life and aesthetic appeal of the underlying material.

The fundamental element of ceramic coatings is silica, which contributes to their hardness and sturdiness. The application procedure commonly includes surface prep work, application of the layer, and curing, which can be achieved via warmth or UV light. When treated, ceramic finishings exhibit extraordinary bonding residential properties, allowing them to adhere highly to a variety of surface areas, including metals, plastics, and glass.

In addition to their protective functions, ceramic layers additionally use convenience of maintenance. Their hydrophobic nature reduces the adherence of dust and crud, making cleansing easier and much less frequent. On the whole, the adoption of ceramic finishings represents a substantial innovation in surface defense innovation, supplying both practical and aesthetic benefits throughout numerous markets.

Kinds Of Ceramic Coatings

Numerous kinds of ceramic coatings are offered, each developed to satisfy specific efficiency needs and applications - Car Detailing. One of the most typical types include:

Silica-based Coatings: These finishings mainly include silicon dioxide and are known for their toughness and chemical resistance. They are widely used in auto and industrial applications.

Titanium Dioxide Coatings: Popular for their photocatalytic buildings, titanium dioxide finishes are usually used in atmospheres where self-cleaning and antifungal buildings are preferable, such as in structure products and automobile surfaces.

Zirconia Coatings: Characterized by their high-temperature security and thermal resistance, zirconia finishes are made use of in applications such as wind turbine engines and high-performance automobile components.

Alumina Coatings: Showing superb hardness and thermal security, alumina finishes are regularly used in wear-resistant applications, including cutting devices and commercial equipment. - Car Detailing

Crossbreed Coatings: Incorporating the residential properties of different products, crossbreed finishings provide improved performance attributes, making them appropriate for distinct and demanding applications.

Each kind of ceramic covering serves unique objectives, enabling customers to choose one of the most suitable option based on certain environmental conditions and efficiency requirements.

Advantages of Ceramic Coatings

Ceramic finishes, in particular, offer numerous benefits that make them progressively prominent among makers and customers alike. These layers are resistant to scratches, chemicals, and UV rays, ensuring that the underlying surface stays secured over time.

Along with toughness, ceramic coverings supply exceptional hydrophobic residential properties, enabling very easy cleansing and maintenance. This water-repellent nature reduces the adherence of dust, grime, and various other pollutants, which can extend the aesthetic appeal and performance of the surface area. Furthermore, ceramic coverings can considerably enhance thermal resistance, making them perfect for applications that sustain heats.

Application Process

When applying ceramic finishes, a careful strategy is necessary to attain optimal results. The application process usually begins with detailed surface area prep work. This involves cleaning, sanitizing, and polishing the surface area to remove all pollutants, including dirt, oil, and prior waxes or sealers. A clean surface makes sure proper attachment of the finish.

Once the surface area is prepped, the following step is to apply the ceramic finish. The covering must be applied in thin layers, as thicker applications can lead to irregular coatings.

After application, the coating calls for a particular curing time, typically varying from a few hours to a full day, depending on the product. Throughout this moment, it is essential to stay clear of direct exposure to dampness or contaminants. A mild buffing might be needed after treating to Clicking Here enhance the gloss and eliminate any type of high areas. Complying with these actions faithfully will maximize the effectiveness and durability of the ceramic layer, supplying a long lasting safety layer for the surface area.

Upkeep and Durability

To make sure the longevity and performance of a ceramic layer, normal maintenance is necessary. Ceramic coatings, recognized for their durability and safety top qualities, require specific care regimens to optimize their lifespan and performance. next The first step in upkeep entails routine cleaning with pH-neutral soap, preventing harsh chemicals that can weaken the covering. It is a good idea to clean the car routinely, preferably every two weeks, to stop the build-up of impurities that might endanger the covering's stability.

Along with routine cleaning, routine evaluations are vital. Search for indications of wear or damages, such as hydrophobic residential properties lessening or surface area imperfections. If necessary, a light gloss might be applied to revitalize the finishing without removing it away.

Furthermore, the application of a booster spray can improve the finish's hydrophobic results and recover its gloss. This is specifically beneficial for finishings that have actually remained in usage for a prolonged duration. Eventually, by sticking to these upkeep techniques, one can significantly extend the life of a ceramic coating, view website ensuring that it continues to supply ideal security against environmental aspects and keep the visual allure of the automobile.

Final thought

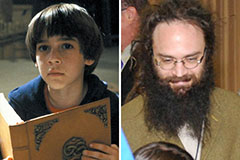

Kel Mitchell Then & Now!

Kel Mitchell Then & Now! Barret Oliver Then & Now!

Barret Oliver Then & Now! Michael Oliver Then & Now!

Michael Oliver Then & Now! Michael Fishman Then & Now!

Michael Fishman Then & Now! Barry Watson Then & Now!

Barry Watson Then & Now!